Manufacturing Process of Acetate Rayon

Acetate Rayon

We know that

Alcohol + Acid --> Ester

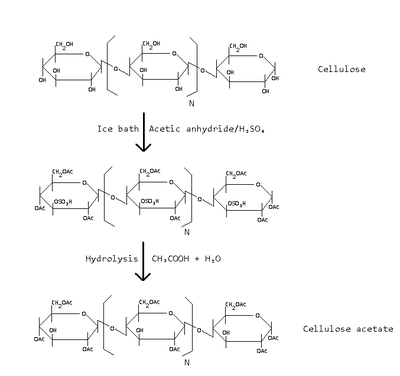

If the cellulose is treated with acetic acid under certain conditions the free hydroxyl groups of cellulose are converted into ester groups.

Manfacture of cellulose acetate

Unlike inthe case of viscose rayon and cuprammonium rayon, where cellulose is dissolved and regenerated, cellulose acetate is manufactured by converting cellulose into a chemical compound of cellulose ( or chem modified cellulose) which is then dissolved in a suitable solvent ( chloroform or acetone) and spun by evaporating the solvent. Thus while viscose and cuprammonium rayons are regenerated fibres, acetate rayon is regenerated modified fibre.

Raw Material

Cotton linters and wood pulp are the most common employed raw materials for the manufacture of acetate rayon

Acetylation Process

We know that

Alcohol + Acid --> Ester

If the cellulose is treated with acetic acid under certain conditions the free hydroxyl groups of cellulose are converted into ester groups.

Manfacture of cellulose acetate

Unlike inthe case of viscose rayon and cuprammonium rayon, where cellulose is dissolved and regenerated, cellulose acetate is manufactured by converting cellulose into a chemical compound of cellulose ( or chem modified cellulose) which is then dissolved in a suitable solvent ( chloroform or acetone) and spun by evaporating the solvent. Thus while viscose and cuprammonium rayons are regenerated fibres, acetate rayon is regenerated modified fibre.

Raw Material

Cotton linters and wood pulp are the most common employed raw materials for the manufacture of acetate rayon

Acetylation Process

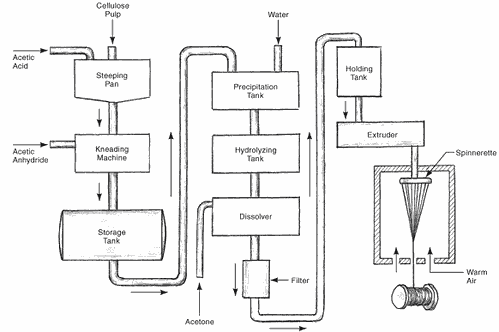

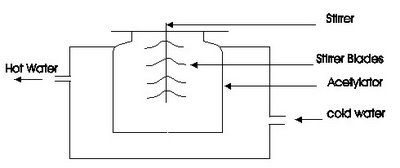

The pretreated purified cotton linters are fed into an acetylator ( closed vessel) containing a mixture of acetic anhydride, glacial acetic acid and a small amount of concentrated sulphuric acid. For every 100 kg of cotton linters, 300 kg of glacial acetic acid, 500 kg of acetic anhydride and 8-10 kg of concentrated su;phuric acid may be used. The acetylator consists of a metal tank having a circular door at the top. The door is sealed after adding the mixture of chemicals and cotton linters. A stirrer having many blades rotates in the acetylator to mix the ingredients thoroughly. The acetylation reaction is an exotherimic reation. Heat is removed by circulating cold water through a jacket fitted to the acetylator. The acetylation reation is completed in 7-8 hours at 25-30 deg c. Triacetate is formed at this stage and it is in the form of a suspension in the acetylation mixture called the acid dope.

Hydrolysis ( Partial Deacetylation)

The acid dope from the above process is stored in jars for ageing. Acetic acid, water and sulphuric acid are added and allowed to stand for 10-20 hours. During this period, called ripening period, partial conversion of acetate groups to hydroxy groups takes place. The mixture is then diluted with water and stirred continuously when white flakes of acetate rayon get precipated. The flakes are placed in a centrifuge and the excess water is forced out of the cage through perforations. The flakes are then dried.

Spinning Solution or Dope

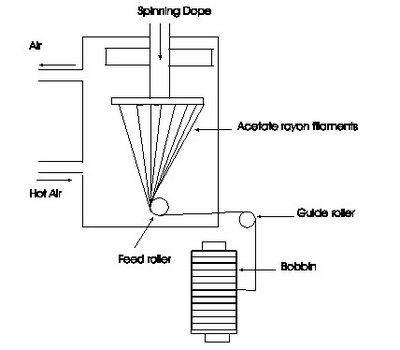

Acetate rayon is manufactured by dry spinning. It is dissovled in a volatile solvent (Acetone) to form the spinning solution or dope. This solution is forced through a spinnerette into a chamber in which hot air is circulated. The solvent evaporates leaving filaments of acetate rayon.

The details are as follows. Dried acetate flakes are mixed with three times the weight of acetone in enclosed tanks which are provided with powerful stirrers. The acetate dissolves slowly in the solvent. It takes about 24 hours for the complete dissolution to give a thick clear liquid called dope. The solution is filtered and deareated.

Spinning Process

Hydrolysis ( Partial Deacetylation)

The acid dope from the above process is stored in jars for ageing. Acetic acid, water and sulphuric acid are added and allowed to stand for 10-20 hours. During this period, called ripening period, partial conversion of acetate groups to hydroxy groups takes place. The mixture is then diluted with water and stirred continuously when white flakes of acetate rayon get precipated. The flakes are placed in a centrifuge and the excess water is forced out of the cage through perforations. The flakes are then dried.

Spinning Solution or Dope

Acetate rayon is manufactured by dry spinning. It is dissovled in a volatile solvent (Acetone) to form the spinning solution or dope. This solution is forced through a spinnerette into a chamber in which hot air is circulated. The solvent evaporates leaving filaments of acetate rayon.

The details are as follows. Dried acetate flakes are mixed with three times the weight of acetone in enclosed tanks which are provided with powerful stirrers. The acetate dissolves slowly in the solvent. It takes about 24 hours for the complete dissolution to give a thick clear liquid called dope. The solution is filtered and deareated.

Spinning Process

The dope is spun into acetate rayon filaments on the dry spinning process. The dope is fed from a spinning tank into spinning cabinets. The dope coming out of the spinnerette travels a distance of 2-5 meters vertically downwards to a feed roller, from where it is guided on to a bobbin at a much greater speed than the speed of spinning. This imparts twist to the filaments.

Properties of Acetate Rayon

Properties of Acetate Rayon

55/20/3s means 55 denier yarn, 20 filament and 3 TPI S side.

Moisture content of sec. Cellulose acetate is 6.5% at 70 deg F and 65% RH.

( Moisture Content= Wt of water in a material /Total wt of material) ( Moisture Regain= wt of water in a material/ oven dry wt of material)

( RH= actual humidity/ humidity of air saturated in water).

Tenacity of Acetate rayon is 1.4 gpd at dry state and 0.9 gpd at wet state.

Elongation at break is 25% in dry state and 35% in wet state

Acetate Rayon is more sensitive to heat. It begins to weaken at 93 deg C. At 175 deg C it becomes sticky and melts at 260 deg C. Like nylon and polyester it is thermoplastic. Thus permanent crimp, pleats and creases can be imparted to the garment under carefully controlled conditions.

Acetate rayon is soluble in acetone, methyl ethyle ketone etc.

Some degeneration takes place when this fiber is exposed to light but not very serious.

It is stable to hot water.

It can also withstand treatment with soap or alkali solution having a pH of not more than 9.5 at temp upto 100 deg C. Therefore it can undergo normal scouring and dyeing operations without affecting the lustre.

It is unaffected by dilute solutions of weak acids but attacked by strong acids. Concentrated organic acids cause swelling

It is resistant to attack by bacteria and fungi. Its low moisture content contributes to resistance to mildew.

It is non toxic and non irritating to skin

Only a few striations ( 2-3) are present in the fibre as can be seen from the longitudinal view. The cross section of the fiber have individual lobes and are round and smooth. It is the smaller number of lobes or serrations of acetate fibres that distinguish the fibre

55/20/3s means 55 denier yarn, 20 filament and 3 TPI S side.

Moisture content of sec. Cellulose acetate is 6.5% at 70 deg F and 65% RH.

( Moisture Content= Wt of water in a material /Total wt of material) ( Moisture Regain= wt of water in a material/ oven dry wt of material)

( RH= actual humidity/ humidity of air saturated in water).

Tenacity of Acetate rayon is 1.4 gpd at dry state and 0.9 gpd at wet state.

Elongation at break is 25% in dry state and 35% in wet state

Acetate Rayon is more sensitive to heat. It begins to weaken at 93 deg C. At 175 deg C it becomes sticky and melts at 260 deg C. Like nylon and polyester it is thermoplastic. Thus permanent crimp, pleats and creases can be imparted to the garment under carefully controlled conditions.

Acetate rayon is soluble in acetone, methyl ethyle ketone etc.

Some degeneration takes place when this fiber is exposed to light but not very serious.

It is stable to hot water.

It can also withstand treatment with soap or alkali solution having a pH of not more than 9.5 at temp upto 100 deg C. Therefore it can undergo normal scouring and dyeing operations without affecting the lustre.

It is unaffected by dilute solutions of weak acids but attacked by strong acids. Concentrated organic acids cause swelling

It is resistant to attack by bacteria and fungi. Its low moisture content contributes to resistance to mildew.

It is non toxic and non irritating to skin

Only a few striations ( 2-3) are present in the fibre as can be seen from the longitudinal view. The cross section of the fiber have individual lobes and are round and smooth. It is the smaller number of lobes or serrations of acetate fibres that distinguish the fibre